Knowledge centre

Thermal transfer vs direct thermal printing, what’s the difference?

Do you no longer see the wood for the trees when it comes to thermal printing? Don’t worry, we’ll help you on your way. With most label printers you can choose between two printing techniques for printing your labels: thermal transfer and direct thermal. Although these two techniques are quite similar in terms of name, there is a noticeable difference in terms of technique.

Choose the right printing technique

Are you about to look for a suitable label printer? Then it is of course important to know which criteria your printer must meet. To determine the right printer, you want to understand the characteristics and techniques of the different options. Each type of printer has its pros and cons.

You will soon see the term “thermal printing” pop up. But what exactly does that mean? Thermal printing uses heating to print labels. Below we explain the two different techniques of thermal printing: direct thermal and thermal transfer.

Direct thermal printing

A direct thermal printer prints your logo, text or image by selectively heating thermal paper as the paper passes under the thermal print head. The top layer, or coating, of the label turns black in the areas where it is heated, thus creating a certain image. Are you curious if you use this? Then scratch the label with your fingernail. Do you see a discoloration on the label? Then you work with a thermal label.

Some features of this printing technique at a glance:

- Easy to use as no ribbon is required, which can have a positive impact on handling costs and production lead time

- This technique is especially suitable for products with a short shelf life

- These labels react to heat, sun and UV light and discolour with prolonged exposure

- Since the print head is in direct contact with the thermal paper, there is a chance that it will be subject to wear and tear.

- This type of label is widely used in logistics, transportation, online shipping & fresh produce

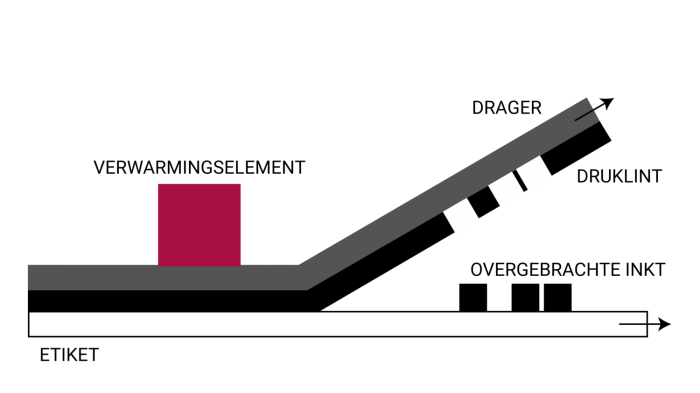

Thermal transfer printing

Thermal transfer printing uses a printing ribbon to print the label. As the label and ribbon are driven together under the printhead, small pixels across the width of the printhead are heated. These heated parts then ensure that the ink is applied to the label.

Discover some advantages and disadvantages of this printing technique:

- Labels are more scratch resistant and remain legible for a much longer period of time

- The print head enjoys a long life when the correct printing ribbon is used

- Choice of ribbons specially designed to provide better protection against scratches, corrosive substances or weather conditions

- Ability to print on a wide variety of materials

- This type of label is used in the medical sector & chemistry, plant sector, food sector, for long-term storage…

Related products

Explore further

Efficient Inventory Management? Discover How Marisan Supports You from Label to Pallet

Blog

A well-organized inventory system involves more than just stacking boxes. It requires smart labeling, reliable packaging, and secure shipping. At Marisan ...

Read moreOrder faster through our webshop!

Nieuws

NogMeerVerdiepen

Order faster through our webshop! Your repeat order? Now just one click away. Good news! From now on, as an existing customer, you can easily place your packaging or label orders online through our exclusive customer webshop.

Read moreLabels that stick (or don’t): choosing the right adhesive for every application

Blog

Labels are more than just carriers of information. They play a crucial role in product recognition, logistics efficiency and traceability. But even the best-designed label won’t perform as intended without ...

Read moreEPR for packaging: who pays the bill for sustainability?

Blog

Duurzaamheid

Knowledge centre EPR for packaging: who pays the bill for sustainability? EPR or Extended Producer Responsibility sounds like a noble principle. And it is: Europe wants to make producers more...

Read moreThe advantages of IndES modules: faster, cheaper, and more sustainable than blister packaging

Blog

Duurzaamheid

NogMeerVerdiepen

Looking for a modern alternative to tie wraps, blister packaging, or twist ties in an industrial production or retail environment?

Read moreThe FSC label: why responsible forest management makes your brand stronger

Blog

Duurzaamheid

NogMeerVerdiepen

Sustainability is no longer a hype, but a necessity. In a world where consumers and companies are making increasingly conscious choices, environmental labels play an important role.

Read moreSilk paper: the elegant and ecological choice for your packaging

Blog

NogMeerVerdiepen

In a world where sustainability and perception are increasingly important, silk paper is gaining popularity as a packaging material. And rightly so.

Read moreLeiepoort Deinze opts for sustainable non-woven carrier bags by Marisan

Case

Scholengroep Leiepoort Deinze attaches great importance to sustainability, equality and small-scale teaching.

Read moreThank you, Jos. Welcome, Karel!

Nieuws

On April 30, Jos closed his chapter at Marisan after 14 years as Purchase Manager. His dedication, knowledge, and pleasant collaboration made him a strong asset to our team.

Read moreWhat is the difference between woven and non-woven carrier bags?

Blog

NogMeerVerdiepen

When choosing the right carrier bag for your company or campaign, you quickly come across the terms woven and non-woven. But what exactly is the difference between these two types of carrier bags?

Read more