Knowledge Centre

PPWR: The new European packaging rules, what do they mean for you?

The packaging industry has been shaken up considerably at the start of this year. With the arrival of the Packaging and Packaging Waste Regulation (PPWR), the European Union is significantly tightening the rules on packaging. Less waste, more re-use and stricter recycling standards will become the new standard. That sounds like a big challenge, and it is. But it also offers opportunities for innovation and more sustainable packaging solutions. In this blog, we dive into the heart of the PPWR and show how Marisan and its customers are preparing for it.

What are the main goals of the PPWR?

- Less packaging waste: no unnecessary layers and a ban on ‘unnecessary packaging’.

- More reuse and recycling: packaging should be easier to recycle and some sectors should switch to reusable packaging systems.

- Use of recycled material: plastic packaging will soon have to contain a minimum percentage of recycled material.

- Single European legislation: no more jumble of national rules, but clear guidelines for all companies producing or using packaging.

The first major changes will take effect from 2030, with further tightening in 2035. So companies need to take steps now to comply with the new requirements.

Specifically, what will change?

1. Stricter requirements for recyclability

From 2030, stricter requirements will apply to the recyclability of packaging. This means that:

- Materials must be easier to recycle.

- Packaging that does not fit well into existing recycling systems should disappear from the market.

- The ‘Design for Recycling’ guidelines come into force. This means that packaging should not only be theoretically recyclable, but also effectively recyclable. And this is often not the case now.

2. Restrictions on excessive packaging

Sometimes you see a product with three layers of plastic, a cardboard box and another plastic film around it. The EU wants to get rid of that. Soon, packaging will have to be as efficient as possible, with:

- Less space and air in packaging.

- No unnecessary layers of packaging unless strictly necessary.

- A ban on packaging designed solely to make the product look bigger.

3. Minimum percentage of recycled material in plastic packaging

From 2030, plastic packaging must contain a minimum percentage of recycled material. This varies by type of packaging, but the intention is clear: less dependence on fossil raw materials and increased demand for recycled materials.

4. More reusable packaging

Certain sectors should switch to reusable packaging systems. Think, for example, of transport packaging and beverage packaging. Especially in the hospitality and retail sector, reuse is becoming the new norm.

Challenges for the packaging industry

While the objectives of the PPWR sound logical, in practice it is often a more difficult issue. We would like to highlight two major, specific challenges for our suppliers.

1. Paper packaging and the EUDR

In addition to the PPWR, another European law is coming that will give paper producers and users a headache: the EU Deforestation Regulation (EUDR). This law requires paper producers, and all subsequent participants in the chain, to state exactly which tree species and regions the paper comes from.

This sounds good in theory, but in practice this is almost impossible for some applications. Paper is often produced in silos where wood pulp from as many as 60 different tree species is mixed. Suppliers can therefore hardly trace which trees eventually end up in the paper. This creates major administrative challenges and possibly even delivery problems.

2. Food and pet food packaging

For (pet) food products, packaging not only aims to be sustainable, but also to keep the product safe and fresh. Many food packages therefore have special barrier layers that protect against moisture, air and bacteria. These barrier layers often consist of multiple materials, such as aluminium-coated plastic or coated cardboard packaging. This makes recycling more difficult. The challenge for this industry is to develop packaging that is both food-safe and recyclable, which is easier said than done.

How Marisan is preparing for the PPWR

1. Moving to mono-material packaging

One of the most important changes we are making is the move to mono-material packaging. What does that entail? Many packages are composed of different materials (e.g. plastic and aluminium), making them difficult to recycle. By switching to mono-materials (consisting of a single material), we make packaging easier to recycle and more suitable for the circular economy. For example, we already have paper bags with paper strings and loop handles in our range. And more to come!

2. Advice and support for customers

The PPWR affects not only packaging producers, but also companies that use packaging. Therefore, we are happy to help our customers with:

- Understanding the legislation: what does the PPWR mean concretely for their packaging?

- Sustainable alternatives: which packaging does meet the new requirements?

- Smart designs: how to ensure recyclable packaging without sacrificing functionality?

The future of packaging: take action now

The PPWR is changing the rules of the game in the packaging industry. Where sustainability was previously a choice, it is now becoming a must. Companies that do not adapt risk their packaging being banned from the market from 2030 onwards. Want to know what the PPWR means for your business and how to future-proof your packaging? Contact us for a no-obligation consultation!

Gerelateerde producten

Explore further

Scratch-proof labels for Surgi-Tec that last

Case

Succesverhalen

Surgi-Tec is a Belgian company known for its high-quality medical implants and innovative solutions to complex surgical challenges. But even the best producers demand packaging and labelling that meets the highest standards.

Read moreEmployee in the spotlight: Louis!

Nieuws

Today we would like to introduce you to our new colleague Louis! Louis recently started working at Marisan as a Customer Service employee. His main task? Prospecting! And he loves following conversations with potential customers to get to know Marisan and our operations better.

Read morePaper mailing envelopes: a smart choice for efficient and sustainable shipping

Blog

Duurzaamheid

NogMeerVerdiepen

Whether you are shipping clothes, documents or other compact products; paper mailing envelopes are an ideal solution. They combine environmental friendliness, ease of use and efficiency.

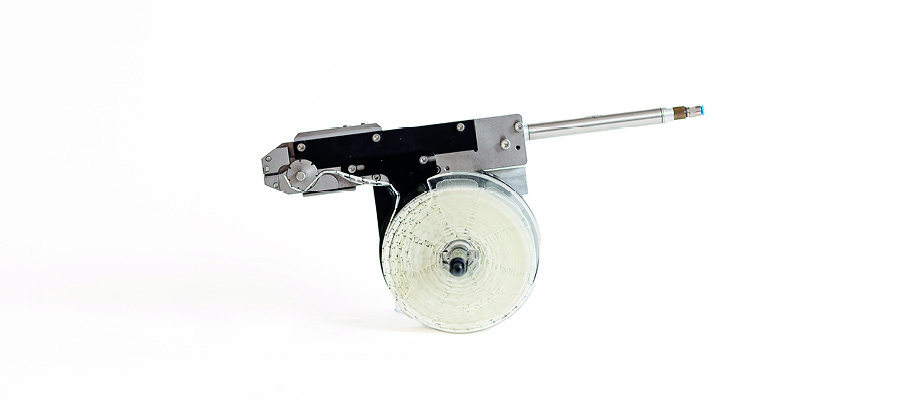

Read moreReady for the sales: maximum efficiency with our price and textile tagging guns

Blog

NogMeerVerdiepen

December is drawing to a close and that means only one thing: the sales are coming! For retailers, this is the time to price, promote or label your products quickly and clearly. Fortunately, this is easier than ever with our price labeler or textile gun.

Read moreWhy stone paper carrier bags are a sustainable choice

Blog

Duurzaamheid

NogMeerVerdiepen

More and more companies and consumers are looking for more sustainable alternatives to traditional carrier bags. Stone paper carrier bags offer an excellent solution, not only because of their innovative material, but also because of the ecological benefits they bring.

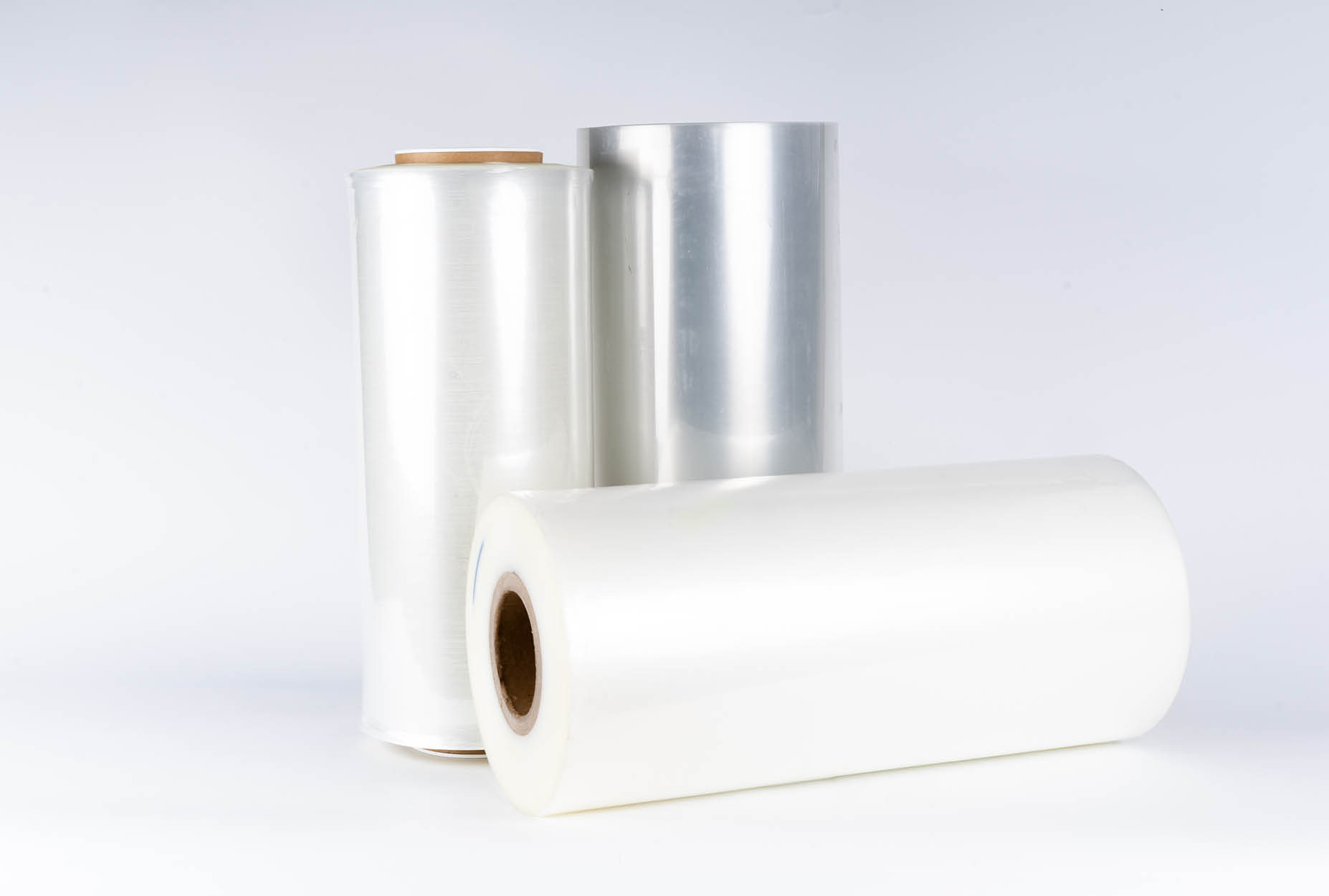

Read moreManual or machine wrapping: which stretch wrap is right for your company?

Blog

NogMeerVerdiepen

Stretch wrap is essential for the safe and efficient shipping of products. It ensures that your loads remain well protected during transport and prevents damage. But when do you choose manual wrapping and when is a machine solution a better choice?

Read moreMarisan continues the excellent service for Eti-Machine customers

Nieuws

NogMeerVerdiepen

On August 31, 2024, Leo, founder of Eti-Machine, closed the doors of his business after more than 60 years. Leo started his company in 1960 as a pioneer in Belgium in the field of labels on rolls. The company grew into a key player on the market, and f.e. became the principal supplier.

Read moreWhitepaper: Packaging solutions tailored to your medical lab or hospital

Whitepaper

NogMeerVerdiepen

In the medical sector, choosing the right packaging solutions is crucial. Whether it’s laboratories, hospitals or pharmaceutical companies, every application requires packaging and/or labels that meet strict standards and specific needs. Our latest whitepaper provides in-depth insights and practical solutions.

Read moreMarketing on the move: carrier bags with your own logo

Blog

Duurzaamheid

NogMeerVerdiepen

Having carrier bags printed with your own logo is an excellent way to give your brand visibility and offer your customers a practical and stylish solution. At Marisan, we understand the importance of high-quality shopping bags that are not only functional, but also an extension of your brand.

Read more