IndES modules

Your alternative to blister packs and tie wraps

Marisan introduces IndES

IndES is the ideal replacement for blister packs and tie wraps. The entire range relies on pneumatic technology. This makes the attachment system extremely flexible, easy to use and a lot faster than manual work. This innovation in consumer goods fixing and packaging offers several advantages. It speeds up performance and is attractive to customers. It’s also more durable than traditional packaging methods such as blister packs, twist tie wraps and cable ties.

No more expensive plastic shields

Another advantage of packaging without a blister pack is that the customer can touch the item in the shop as it is not hidden away behind a plastic shield. IndES is also cheaper than blister packing. Last but not least, it is much more environmentally friendly. The packaging material is quickly and easily removed, significantly reducing packaging volume and making your packaging more customer friendly and sustainable.

The benefits at a glance

- Eliminates consumer-unfriendly or blister packs

- Replaces fiddly twist wires and cable ties

- Lower the packaging cost price per unit

- Is customer and environmentally friendly

- Can be removed quickly and easily

- Significantly reduces packaging waste

The most obvious applications are:

- tools

- toys

- household items such as kitchen utensils

- socks and gloves

- towels

- floor and doormats

IndES packaging module: powered by Avery Dennison

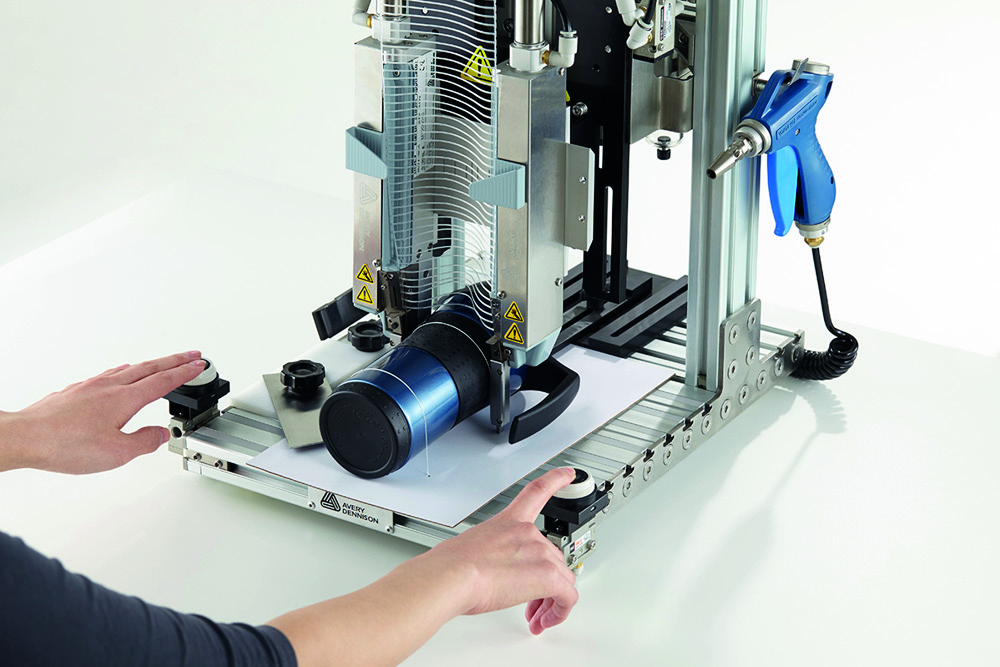

The unique design of the IndES system from Avery Dennison, , protects items on flat card surfaces or multi-level card designs. With lengths of 15 mm to 150 mm, the strong, flexible staples can handle a wide range of product shapes and sizes. This versatile system can be used as a stand-alone unit or integrated into the high-volume packaging lines automated by Marisan.

Our IndES machines

In order of automation, we have several machines available.

R4

Hand-operated device that requires only air pressure to push the attachment (tagging attachment, paddle tag) through the module, over the product and through the header card. You move the device itself up and down by hand.

R6 – R10

A device where both the downward movement and the shooting itself are pneumatic. These devices operate with 1 IndES module.

- R6: The products are placed on a base plate or in a mould

- R10: The products are placed over a nozzle leaving a part free of the attachment. This machine is mainly used for attaching gloves or socks.

R8 – R12

These devices have 2 IndES modules.

- R8: Two modules that simultaneously attach a product to a header card. These machines are mainly used in the mat and carpet industry. See how this machine works in this video.

- R12: Here, two modules are attached to movable arms so that products can be attached from various positions in one shot.

R30

This machine is a fully automatic application for kitchen utensils, tools and toys. The operator only needs to feed the product into the machine. The insertion of the header card, attachment at various stations and ejection of the finished product is automatic. The R30 is therefore only applicable for large production runs. Watch the instructional video here.

The R6 and R8 machines are also built for EHD (Extra Heavy Duty) applications. This includes much heavier attachments such as heavy mats and car mats. These EHD attachments are rigid and non-elastic.

Industrial attachment success stories

Explore further

How packaging influences customer experience and brand perception

Blog

Duurzaamheid

NogMeerVerdiepen

In the dynamic world of marketing and branding, packaging plays a crucial role in how consumers perceive and experience a product. At Marisan, experts in innovative packaging solutions, we understand that the right packaging not only catches the customer's attention, but also leaves a lasting impression.

Read moreGuidelines for a sustainable textile sector

Blog

Duurzaamheid

NogMeerVerdiepen

For today's textile companies, it is crucial to take responsibility. More so: ignoring sustainability and circularity can have major consequences for brand reputation. Fortunately, there are already numerous evolutions today that promote sustainability. The distribution sector is betting on reusable packaging.

Read moreMarisan introduces innovative Loop Tagger during webinar

Webinar

NogMeerVerdiepen

From kitchenware and tools to toys and textiles: a lot of industrial products need one or more attachments. Such a procedure is labour-intensive for operators and requires both time and budget. At Marisan, we have been working behind the scenes for some time on an innovative method to attach one or more cards to products better, faster and automatically.

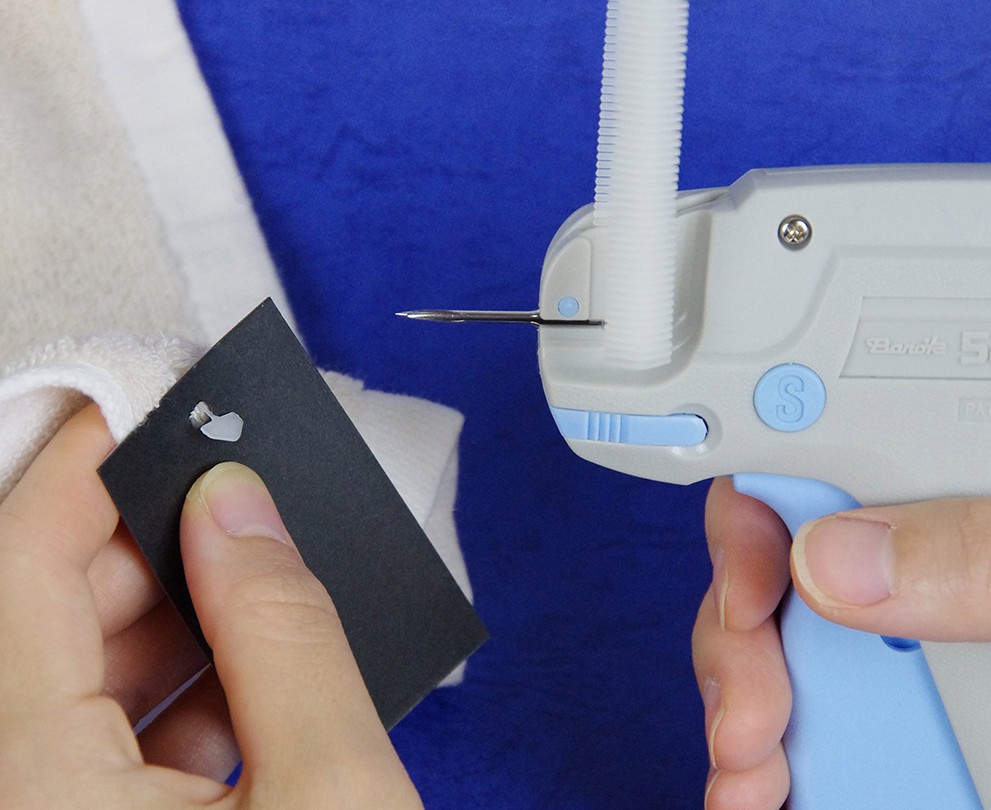

Read moreCombining Banok pistols and textile pins

Blog

NogMeerVerdiepen

In this article you will find the Banok trees in the forest. If you ask yourself: "Which Banok pistols can you combine with which types of attachments?" , then a handy overview follows in the attached document. There are 4 types of pistols.

Read more